Ultimate Guide To Press Brake Tooling

Estimated reading time: 10 minutes

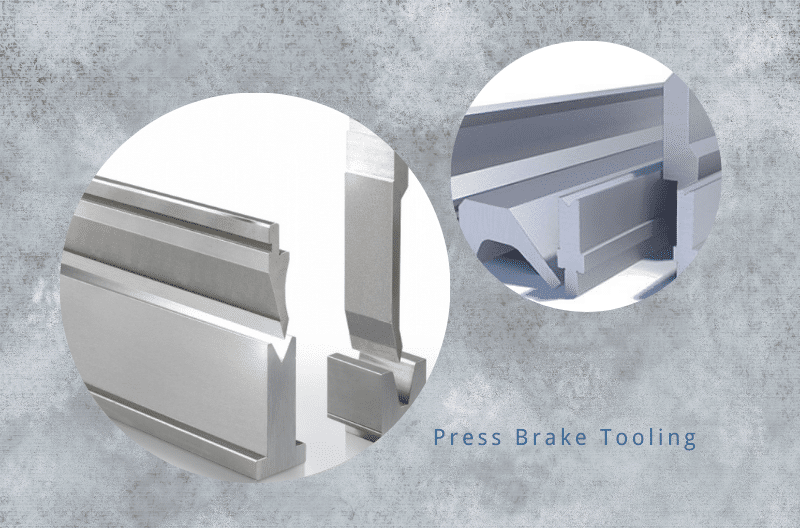

The operation of the press brake may seem simple: the operator takes a metal plate or plate and slides it between the two tools. You will see the top tool (punch) descend towards the lower tool (die) to bend the part. The whole press brake tooling process is complete.

The amount of things that happen makes bending one of the most complex and least known processes in metal manufacturing. It all starts with how the punch and die of the machine interact with the sheet metal.

Basic Knowledge of The Radius

Some engineers in the industry told stories about receiving solid CAD models of sheet metal parts from customers, seeing the bends, and discovering that there is no radius at all. Modern software makes this situation less common, but it proves that even people in manufacturing are not familiar with sheet metal bending. So here is the most basic knowledge.

Each bend has an angle and radius. The bending angle is intuitive, but when you look at the part drawing and measure the molded part, you need to know whether the specified angle is the inside or outside of the bend.

But what about the radius? Metal manufacturing uses the term radius to describe curves in sheet metal, plates, and the tools used to create them. Recall the geometry of middle school and high school: draw a circle, place a point in the center, and then draw a straight line from that point to the edge. The distance of that straight line is the radius. The smaller the radius (the shorter the line), the smaller the circle and the sharper the curve of the circle.

On some drawings, you may see a bend with a specified radius; if you see R .120 with an arrow pointing to the inside of the bend, it means the inner bend radius of the bend (that is, the radius along the inner surface of the bend) Is 0.120 inches. Radius is not the distance between the start and end of the bend (there is another term). Instead, imagine drawing a circle whose edge overlaps the curved curve. The inner bend radius of the circle (and therefore the bend) should be 0.120 inches.

What Happens When The Metal Is Bent

When the press brake bends, the metal stretches slightly. This is related to the compression and expansion properties of the sheet or sheet when it is bent. Consider the cross-section of the sheet metal thickness. Close to the outside of the bend will expand, close to the inside will be compressed, and the interaction of these forces pulls the neutral axis (the boundary between compression and expansion) toward the inward bending radius. Bender professionals define this transition as the k-factor, and it is this transition that causes the metal to elongate or grow.

The advantage (and modern software) uses the k-factor and other variables to explain this elongation. It involves calculating the bending allowance (the length of the neutral axis of the bending) and the bending deduction-the amount you deduct from the original size to take into account the elongation, so when the workpiece is bent, its size “grows” “To the desired size.

If you are a complete novice, this may be a bit too weedy. But, at least in a general sense, understanding what happens when metal is bent can provide you with a good starting point to learn more.

When you see the operator picking up a laser-cut or stamped metal plate, he slides or stops the finger behind the punch and the die, thereby keeping the blank in the correct position for bending. If the workpiece is leaned against If it is unstable on the stop, or there is a problem with the finger position of the rear stop, the bending will make mistakes.

The shape of these tools-the upper punch and the lower die-to a certain extent determine how the bending occurs. Conventional punches have a punch tip radius (the smaller the radius, the sharper the punch) and the punch angle. The lower V-shaped mold has a mold opening (also called a V-shaped opening or mold width). The angle of the V is the mold angle, and the opening that transitions to the V is called the mold shoulder radius.

The angle of the punch should not be greater than the angle of the die. If the punch with a larger angle is lowered into a V-shaped die with a smaller angle, the tool may be damaged and a dangerous situation may be caused.

Looking around the store, you will see fists of various shapes, and for most fists, you may be able to tell where the angle is. This is the angle at which the metal leads to the tip of the punch, which touches the metal. However, if your workshop bends a large workpiece into a large radius, you may also see a round punch; there is a large round rod at the end of the punch body instead of a tiny punch tip. So what is its punch angle? Unless customized in some way, the punch angle of the large round punch is 90 degrees.

Bending Method

The operator begins to bend, and how the blank interacts with the punch and die depends on the bending method used. Regardless of the bending method used, the beginning of the bending cycle is the same: the punch pushes the sheet into the mold opening and slides it over the radius of the mold shoulder on both sides of the V shape.

However, from here on, the bending action depends on the bending method used. If you work for a general manufacturer of old press brakes, you may bottom out. The punch squeezes the metal plate until it “bottoms” at the bottom of the die, punching the punch radius to the bend and forcing the metal plate against the angle of the die. When making the bottom, the punch tip radius determines the inner bending radius, and the die angle determines your bending angle.

The wider mold also reduces the bending force required to create the bend. Thicker materials require more force to bend, so larger press brakes with larger mold openings are usually required. Choose a mold opening that is too narrow for work, and you may damage your machine, tools, and yourself.

Also in air bending, the angle of the punch and die has no direct effect on the bending angle. Conversely, the bending angle depends on the distance the punch tip descends to the die opening, sometimes referred to as the penetration depth.

The mold opening also controls your minimum flange length, which is the narrowest bend you can make with the tools you have. You need to place the workpiece on the shoulder of the mold in a stable manner. Otherwise, once the punch starts to push down, the workpiece will fall into the mold space.

In air bending, choosing a narrower die angle can increase the penetration depth to solve spring back, which is the tendency of the metal plate to bounce slightly after the punch releases the bending pressure. Narrower mold angles also allow you to bend narrower flanges—that is, you can have a lower minimum flange requirement—though again, shrinking the mold opening can significantly increase the forming tonnage.

You may hear the professionals around you say that the mold opening they choose is several times the thickness of the material. There are many ways to choose the best mold for the job, and the calculation method varies with material thickness, strength, and many other factors. But the most important thing is: when people choose a mold, they want to choose a mold that can help them best shape the workpiece while keeping the forming tonnage safely below the limit that the machine and tools can handle.

Planing And Precision Grinding Tools

Back on the first day of work, you will see the operator pull the punch and die from the cart. What tools are they? Well, depending on the type of bending you are doing, a warning sign might be how the operator measures their parts. If all you see is a tape measure, the brake will most likely not bend for precision work. If the bending angle is within 1/4 inch, the part is fine, and the customer may not be picky about the inner bend radius.

In these operations, you may see some planning tools with planers, named after the way they are made. These tools are divided into very long sections, which can be used as-is or cut into shorter lengths. If they are cut, they need to be labeled so that if the work requires longer tools, they can be reassembled in the exact order and direction of the cut. If you don’t match these parts correctly, these tools may cause serious accuracy problems.

Planing And Precision Grinding Tools

Tool Type

Tools in this industry are divided into several categories, including American tools, European tools, and new standard tools. One difference between them is how the tools are installed on the press brake and how the bending force flows through them. Each tool type has its advantages and disadvantages. As a novice, you don’t need to delve into the weeds, but it’s best to understand which types are used in your workshop, how they are properly installed on the machine, and what impact the reversal tool will have.

Stage Bending, Closing Height, And Back Gauge

Looking around the workshop, you may see that some machines have only one punch and die, while other machines may have multiple tools placed on the press brake. If the operator sets these up in the right way, they can perform phase bending-that is, transporting parts through multiple bends on one machine.

The setup seems simple, but it is not. On the one hand, all tools in this setup need to share the same closing height of the space between the punch (directly above the tool) and the bed at the bottom of the stroke (under the tool). Installers may use tools designed with universal closing heights, or they may use spacers and risers to lift each die to match the corresponding punch.

Since modern software can program the back gauge movement and simulate complex bending sequences, this setting has become more common. In the past, the operator had to manually turn the hand crank to move the back gauge finger to the correct position. And these positions are limited, which in turn limits the way the operator can slide the workpiece against the back gauge before starting each bend. Now the machine moves the back gauge to the desired position. Some parts still require creative measurement solutions, but it can be said that the back gauge fingers are more capable than before.

This article allowes me to learn a lot about the press brake tooling.Thank you.

Thanks for your support.